igniting innovation Leading Carbon Brushes

Specializes in the production of carbon brushes for mechanical equipment, power tools, household appliances, industrialmotors, DC motors, and graphite products.

igniting innovation Leading Carbon Brushes

Specializes in the production of carbon brushes for mechanical equipment, power tools, household appliances, industrialmotors, DC motors, and graphite products.

igniting innovation Leading Carbon Brushes

Specializes in the production of carbon brushes for mechanical equipment, power tools, household appliances, industrialmotors, DC motors, and graphite products.

igniting innovation Leading Carbon Brushes

Specializes in the production of carbon brushes for mechanical equipment, power tools, household appliances, industrialmotors, DC motors, and graphite products.

igniting innovation Leading Carbon Brushes

Specializes in the production of carbon brushes for mechanical equipment, power tools, household appliances, industrialmotors, DC motors, and graphite products.

igniting innovation Leading Carbon Brushes

Specializes in the production of carbon brushes for mechanical equipment, power tools, household appliances, industrialmotors, DC motors, and graphite products.

About Us

About Us

Yuda Carbon owns over 15 years of manufacturing experience

Haimen Yuda carbon co., Ltd is committed to exporting graphite and carbon products, including several areas, such as power tools, household appliances, automobile, industy and customized service. Yuda Carbon owns over 15 years of manufacturing experience, covering an area of over 1,000 square meters, employs over 100 staff members, and the annual output value of the company is more than 40 million. Yuda Carbon Business philosophy is first-class talent, first-class products, first-class service.

WE PROVIDE YOU WITH TAILORED SOLUTIONS USING OUR EXTENSIVE INDUSTRY EXPERIENCE.

+

Year experience

- Mechanical Equipment

- Power Tools

- Industrial Motors

- Household Appliances

- DC Motors

- Graphite Products

PRODUCT

PRODUCT

Our latest carbon brush product Classification.

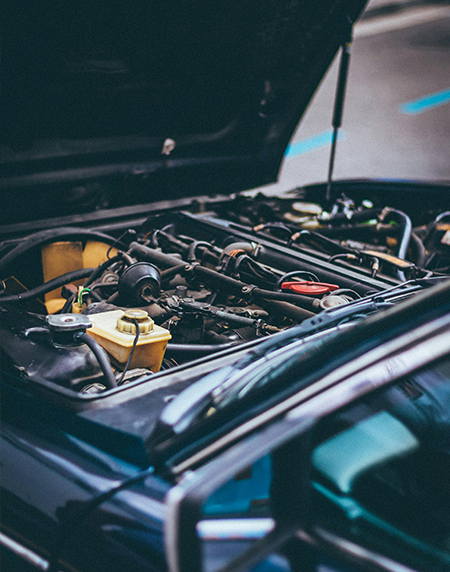

INDUSTRY

INDUSTRY

Carbon brushes are used in various

industry scenarios

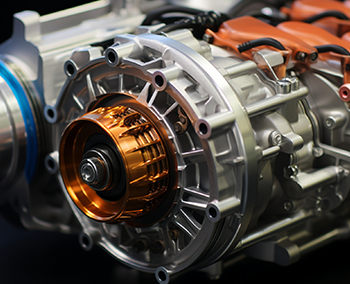

MOTOR MANUFACTURING

Reduce electricarcs, enhancemotor output power, decrease the contactpressure between the brushes and the rotor, reduce the motor load.

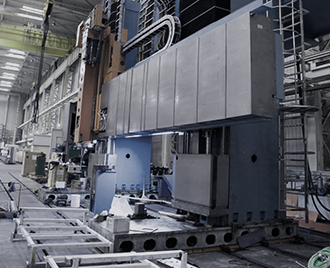

MECHANICAL EQUIPMENT

Brushes are widely used in generators transportation vehicles, industrial control systems, power systems, electric motor drive systems.

POWER TOOLS

Carbon Brushes serve to transport current,conduct electrical commutation,and maintain a stable supply of current in tools such as electric saws,electric drills.

HOUSEHOLD APPLIANCES

Carbon brushes are widely used in various household appliances to transmit electrical energy,ensuring effective transfer and normal operation.

LOWER PRICES

We use advanced technology to reduce costs,resulting in prices that are lower than our peers.

QUALITY ASSURANCE

From material selection to proc-essing and production, we strictly control every link in the chain.

COMPLETE SERVICE

Provide professional personnel to assist customers with installation and maintenance.

FAST DELIVERY

From order placement to production and then to shipping,it is generally completed within a month.

Faqs

Faqs

Have Questions in Your Mind? Get the Answers Now

Why do our carbon brushes have a short life?

The reasons include slip ring surface friction, high pressure from the compression spring, different materials of carbon brushes, unbalanced current distribution, excessive current density, and other factors.

Why is the noise from our motor so loud?

There are many reasons for the loud noise of motor, such as bearing damage, loosening of parts, motor resonance, and uneven motor load, among others. Specific situations require specific analysis.

What is our minimunm order quantity?

Generally, the minimum order quantity is 100 pieces, but it might be less; the exact number is subject to discussion.

When will the delivery be made,and what mode of transportation will be used?

The delivery date depends on the size of the order.Generally, it is mainly shipped by courier.

Can you provide free samples?

Please contact us for further communication.

Testimonial

Testimonial

Customer reviews of us

There are many variations of passages of Lorem Ipsum avalable, but the majority have suffered alteration in some form, by free injected humour, or randomised words which don't look even slightly believable.

Your company's tools and services exceeded my expectations. The tool is easy to operate and greatly improves my work efficiency. Customer service is very responsive and efficient in resolving issues.

During the cooperation, we established a deep trusting relationship and achieved the goal of mutual benefit and win-win results. We look forward to future cooperation and expanding our market share together.