BLOG

The variety of carbon brushes has also increased with the development of the electric motor industry.

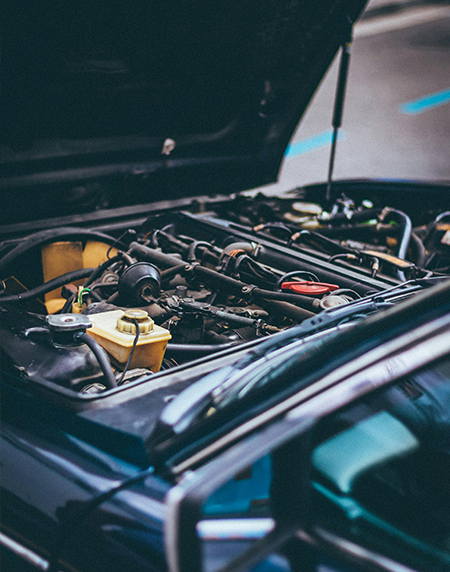

Carbon brushes are suitable for various electric motors, generators, and shaft machines. They are used in the commutators or slip rings of electric motors, serving as sliding contact bodies for current introduction, and are characterized by good electrical conductivity, thermal conductivity, and lubricity, as well as certain mechanical strength and commutation spark instincts. Almost all electric motors use carbon brushes, which are an important component of the motors. They are widely used in various AC and DC generators, synchronous motors, battery DC motors, crane motor slip rings, and various types of welding machines. With the development of science and technology, the types and operating conditions of electric motors have become increasingly diversified, requiring brushes of various grades to meet these demands. Therefore, with the development of the electric motor industry, the types of carbon brushes have increased. For ease of use and management, many carbon brushes have been classified. Currently, the main classification methods popular both domestically and internationally include:

1. According to the hardness of the material, they can be divided into soft carbon brushes, medium-hard carbon brushes, and hard carbon brushes.

2. Based on the application of the carbon brushes, they can be categorized into steam turbine generator brushes, rolling mill motor brushes, traction motor brushes, automotive and tractor motor brushes, electric tool brushes, and aircraft motor brushes, among others.

3. Based on the color of the carbon brushes, they can be divided into black brushes (made from pure carbon graphite materials) and colored brushes (made from copper and other metal materials combined with graphite).

Leave a Message